Most RO machines work the same way, with pressure being the key. Solvent (water) with solutes (minerals) flows in to a pressurized vessel, with a semi-permeable thin film membrane.

For example, the mini-RO machines pictured at the start of this post, require the feed water pressure to be 150 Psi or even higher to work properly. The pressure needed depends on the membrane used.

This membrane allows the water to pass through it, but not the dissolved solids. It’s the pressure which pushes the water through the membrane, leaving the impurities behind.

These impurities are then flushed from the system as dirty water, usually to the drain. These RO machines remove around 99% of the dissolved solids, recovering roughly 50 to 75% of the water which passes through the machine.

It really depends how “dirty” the water is. The “dirtiness” of the water is measured in total dissolved solids (TDS) in parts per million (ppm). When using my system in Shanghai (pictured below), the water usually goes from a TDS count of around 300 to 2ppm.

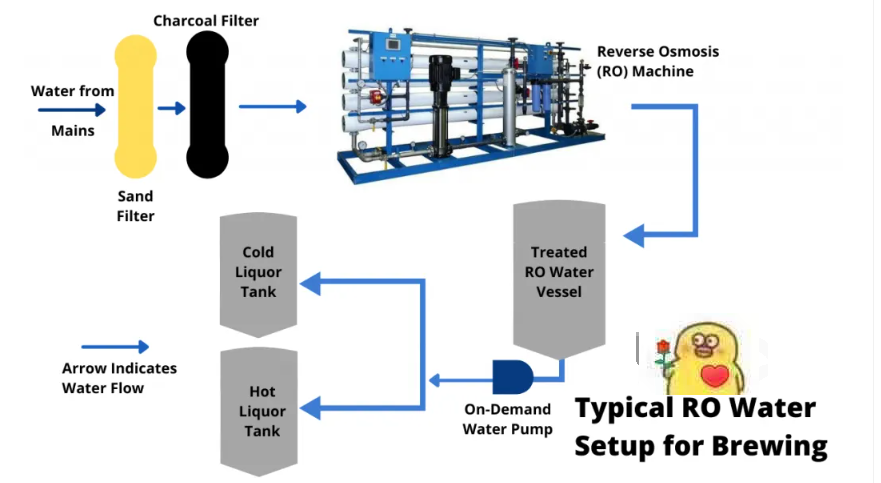

The water in our brewery actually goes through a charcoal filter (to remove chlorine) and a sand filter, before entering our RO machine. The treated water is stored in a tank for use when needed, in the brewery.

Here, I’m going to explain what a basic RO setup looks like. Which is sufficient for most breweries. It’s the same set-up I have at the brewery I’m currently in Shanghai.

Some brewers will suggest different setup having a reason for it. Here’s though I’ve put together a diagram, to show a typical brewery RO system.

Now in this setup above, if the water pressure isn’t sufficient from the mains. You may need another reserve tanks filled with untreated mains water. This reserve tank like the treated RO vessel in the diagram above, has an on-demand water pump.

This pump will automatically begin pumping water to the RO machine when needed. It’s as simple as turning on the machine; which opens a valve, automatically turning the reserve water pump on.

If you don’t have pre-treatment like the charcoal and sand filter above, the brewery needs a bigger RO machine, as there’s more processing to do.

So, the untreated water first passes through a sand filter which catches things like small particles, sand and grit. It then goes through a charcoal filter which removes some organisms, reduces chlorine, pesticides, solvents and other stuff.

This water will still have dissolved solids like calcium, nitrates and fluorides in it. This is where the RO machine comes to the rescue, removing 99% of these impurities and minerals giving the brewer a “blank canvas”. Which they can build back up with brewing salts, to produce a beer truer to style.

There are some downsides to using an RO machine. There’s cost to running the machine using electrical power. An RO machine will take up valuable floor space in a brewery too.

Plus, as we’ve said before, there’s waste water which goes to the drain. Depending on the water source and how “clean” it is, you can end up with as much wastewater as treated water.

Typically, an RO machine recovers between 50 and 75% of the water which flows through it. If the water you’re treating is dirty, with a high concentration of dissolved solids, a lot of wastewater will be produced.

This is why I’d always recommend some form of pretreatment, such as the sand and charcoal filters pictured below, which I’m using now.

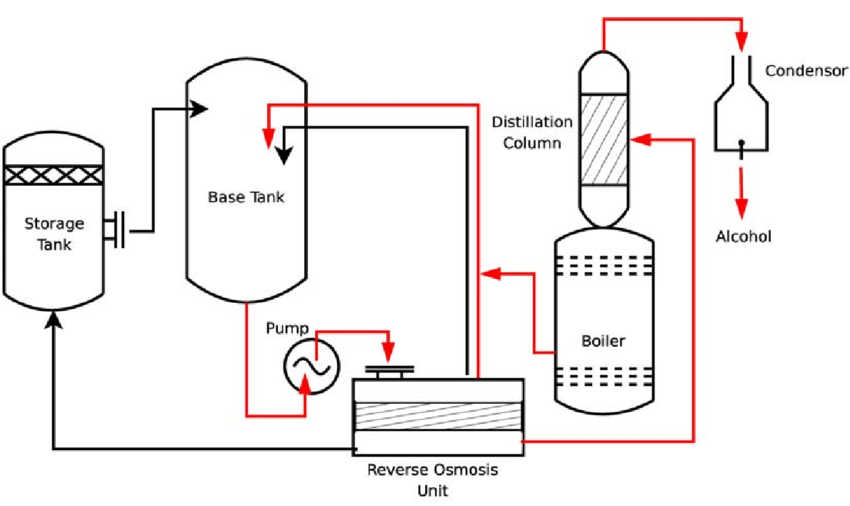

Reverse osmosis water treatment technology development makes it in all water desalination method occupies a leading position, at present the world-wide reverse osmosis device capacity per day has more than 12 million / ton, since the 1990s, each year is still in 20% of the rate of increase. In addition to the use of reverse osmosis in brackish water and seawater desalination, it is also widely used in a variety of fields such as pure water preparation, wastewater treatment and concentration and recovery processes for drinking water, beverages and chemical products.Yes, there is a bigger upfront cost but you’ll waste less in the long run, as the water treated by the machine will be much cleaner.

Even with the downsides listed above; RO water is a prudent choice for brewers wanting greater control over the beers they produce.

There are only four main ingredients in beer so, having full control over one of them (the water), is always going to make the beer brewed, better.

For example, in another article on this site, we discuss how the chloride to sulfate ratio of brewing water effects the refined bitterness of a beer. Knowing your water will be consistent every time using an RO machine, means hitting mash pH is much easier too.

Did you know mains water often comes from many sources? Throughout the year local authorities can switch where you water comes from. Without an RO machine, you’re brewing water can be wildly different, from one month to the next.

It means the water needs analyzing regularly in the brewery to ensure the water additions are still correct. Having an RO machine allows a brewer freedom from the constraints of geography and local water chemistry.

Whether brewing a German Pilsner of dry stout; it doesn’t matter if you begin with a blank canvas and then build the water back up with the correct salt additions.

Running most RO machines is easy enough. They pretty much look after themselves. For instance, the machine I’m currently running, the only real maintenance is replacing the PP (polypropylene) filter cartridges every 3-months or so.

If the water entering the RO machine is lower than 500ppm (parts per million), then changing the PP filters every 3-months is enough. Obviously at the same time you’re changing the filters, ensure the inside of the filter housing is cleaned too.

f the water is dirtier (above 500ppm), then I have to change the filters more often. In reality, I do a visual check every month, to see how dirty the cartridge PP filters are.

On a day-to-day basis when I run the machine, I need to check the two floats (pictured below – ringed in red) are balanced (at the same level). Which is simple as turning the valve (ringed in blue), to adjust the flows.

Otherwise, the only other concern, is ensuring the untreated mains water tank feeding the RO machine doesn’t run dry. Other RO systems may have more actions needed for preventative maintenance; it really depends on the system.

However, in general as I said before, they kind of look after themselves. And there you go; we’ve covered the main aspects RO water use and running an RO machine in a brewery.

I hope our post today on how to use reverse osmosis in brewing has proved useful.

As I say this article came together when people started reaching out. Asking about the mini-RO machines pictured at the start of the post, which can treat 1,200 gallons of water per day. The unit price is US$ 1,250.

I often have people enquiring about RO machines pricing, of units made in China. As in many other countries units are harder to source, and much more expensive to buy.

I like having an RO machine. It provides a blank canvas from which to build the water back up, with the correct salt additions. Allowing me to make a beer truer to style.

However, I always advise clients to get their water analyzed first, as in some places an RO machine isn’t needed.

For example, when I brewed in Yerevan, Armenia we didn’t need an RO machine. As the water was similar to that of Pilsen, being low in mineral content.

As you can also contact me directly on your favorite platform by scanning the relevant QR code below, adding me and messaging me directly.

For now, thanks for reading, have a great day and happy brewing.

If you have any feedback or follow-up questions then please feel free to contact me at:

Tips for Using Home Water Purifier Filter Cartridges

Tips for Using Home Water Purifier Filter Cartridges

The Battle of Four Membranes: Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis—Which Reigns Supreme in Water Purification?

The Battle of Four Membranes: Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis—Which Reigns Supreme in Water Purification?

Don't Pay for Stupidity! The Ultimate 2026 Water Purifier Guide: Selection, Pitfalls, and Maintenance All in One Article

Don't Pay for Stupidity! The Ultimate 2026 Water Purifier Guide: Selection, Pitfalls, and Maintenance All in One Article

Working Principle and Core Technology of Water Softening Equipment

Working Principle and Core Technology of Water Softening Equipment