Hello everyone, today Susan is here to answer some questions about water treatment equipment, hope it can help you.

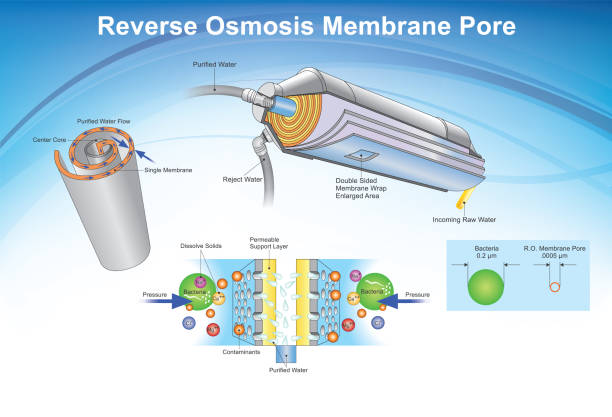

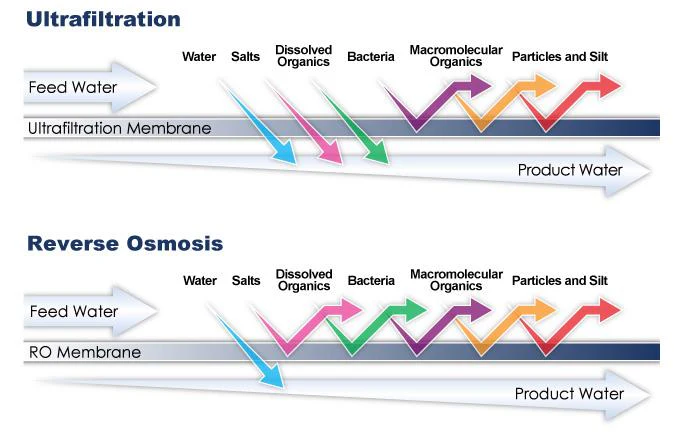

Ultrafiltration membrane and 0 reverse osmosis membrane are both industrial filter membrane, in the production of industrial water filtration have a great role, but these two membrane elements are different in many ways. Understand the difference between the two before you can make a better choice.

The difference in filtration precision

The difference in filtration precision

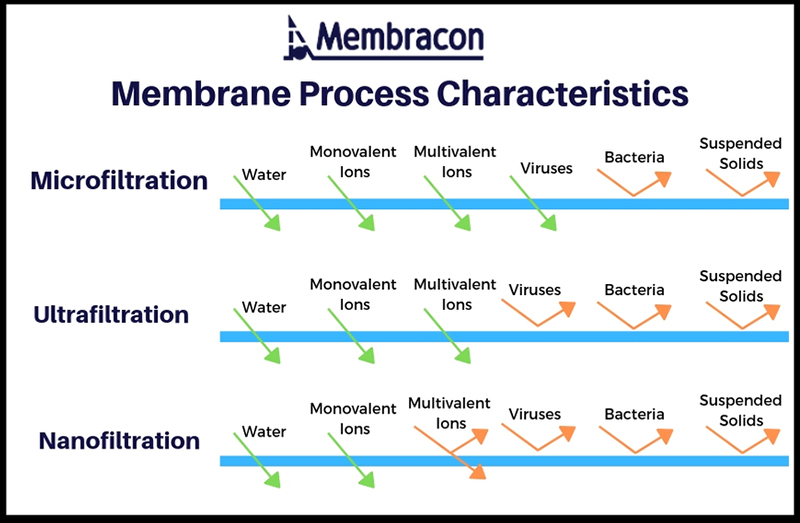

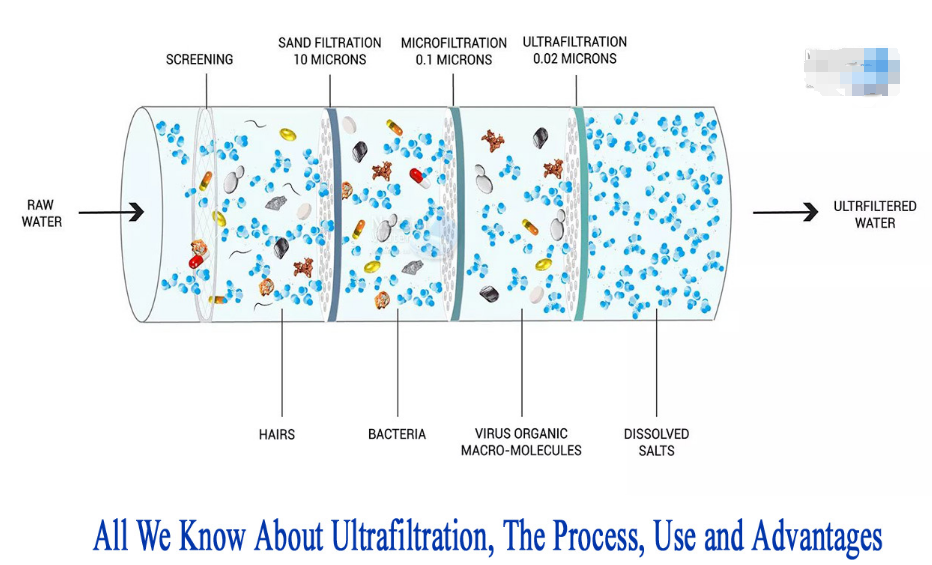

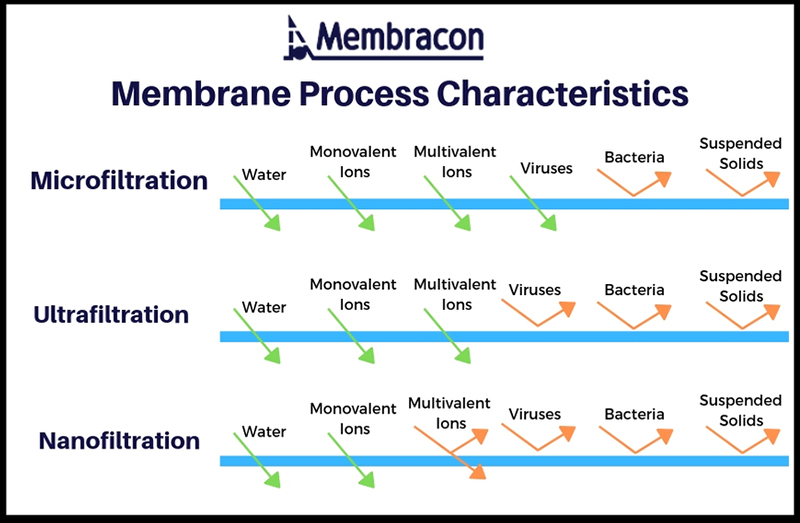

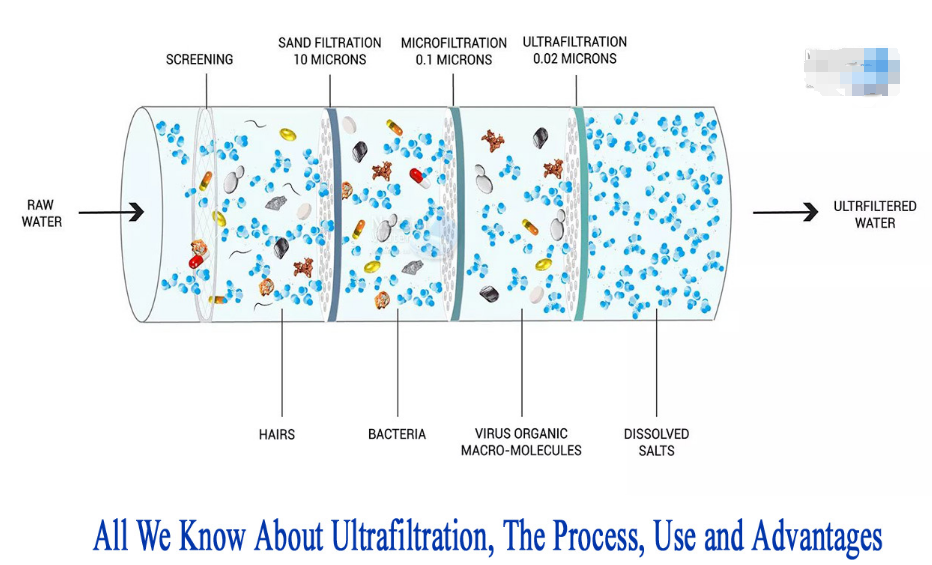

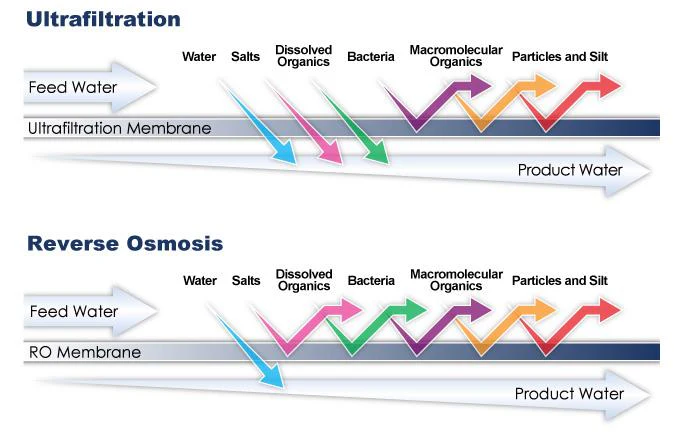

In the industrial filtration system in the use of various membrane elements, membrane element filtration precision from low to high order microfiltration membrane < ultrafiltration membrane < nanofiltration membrane < reverse osmosis membrane ultrafiltration membrane precision is 10um, reverse osmosis membrane precision is 0.0001um, of course, this refers to the highest filtration precision, in practice due to the use of internal or external factors, the actual filtration precision is generally less than the ideal filtration effect.

Material difference

Material difference

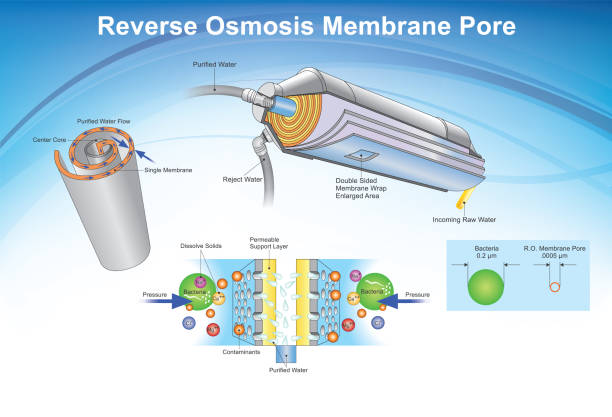

Ultrafiltration membrane is generally made of polyvinylidene fluoride (PVDF), which has high mechanical strength and can ensure high integrity and durability under normal operating conditions. Reverse osmosis membrane is generally made of aromatic polyamide, which shows excellent performance in substance removal and operational durability. Composite ro membrane is mainly composed of three parts: separation function layer, polysulfone porous support layer and polyester non-woven fabric base layer.

Process Differences

Process Differences

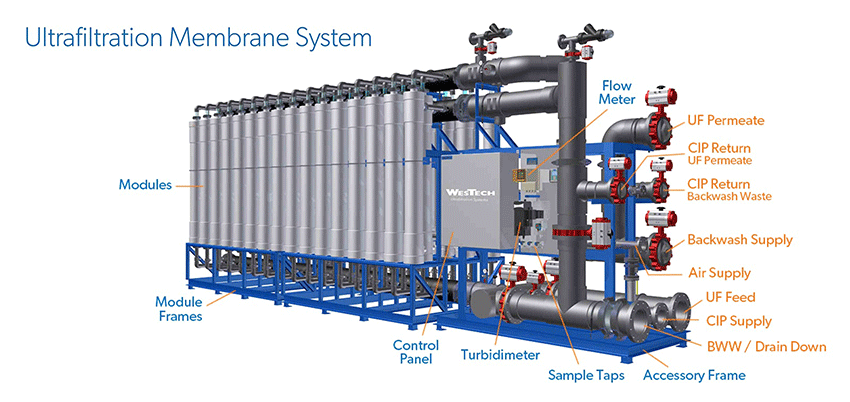

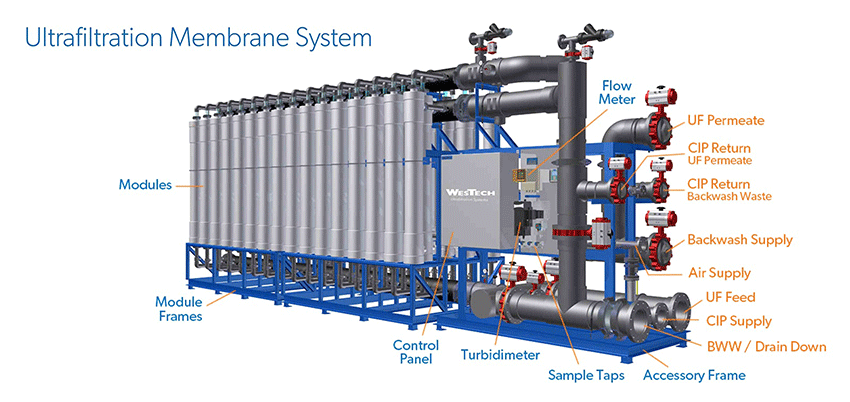

Ultrafiltration membrane is usually installed in the industry for industrial water filtration precision requirements are not high, can be installed directly behind the multi-media filter or water tank. Reverse osmosis membrane due to the higher precision, for the feed water requirements are also higher, generally reverse osmosis membrane in front of several filtration links, generally multi-media filter + security filter.

In addition, industrial filtration in order to improve the quality of water produced by ro, usually use the second level of ro filtration, so as to ensure that the removal rate of pollutants in the produced water is greatly improved.

Difference in desalination rate

Difference in desalination rate

Ultrafiltration membrane desalination rate of more than 90%, reverse osmosis membrane desalination rate of more than 99.3%, reverse osmosis membrane desalination rate is higher than ultrafiltration membrane.

The difference between the technical difficulty of ro reverse osmosis membrane technical difficulty lies in not only to maintain high precision, but also to maintain the stability of the membrane element structure, in the very high pore size, the membrane filament structure but also to maintain stability is very difficult. And ultrafiltration membrane first on the precision is lower, the production difficulty is also lower.

The difference of application

The difference of application

0 reverse osmosis membrane is mainly used in industrial pure water, ultra-pure water production, mainly used in chip industry, semiconductor industry, biopharmaceutical industry and other industrial water treatment filtration. Ultrafiltration membrane is mainly used in food cheese dairy products filtration, electrophoresis paint coating filtration, automobile manufacturing, home appliances and other industrial cathodic and anodic electrophoresis coating, municipal sewage, industrial wastewater recycling filtration in the use.

How to select ultrafiltration membrane and ro reverse osmosis membrane?

1. Choose according to the filtration precision,

How to select ultrafiltration membrane and ro reverse osmosis membrane?

1. Choose according to the filtration precision, if the precision requirement for industrial water is relatively high, must use pure water or ultra-pure water, it is best to choose ro reverse osmosis membrane.

2. Selection according to the use of the environment, if it is the reuse of wastewater, tap water purification treatment, industrial wastewater treatment, municipal wastewater treatment, then the choice of ultrafiltration membrane is appropriate. If it is semiconductor, aerospace, seawater filtration and other use of the environment, then the choice of RO reverse osmosis membrane is most appropriate. Industrial filtration, ultrafiltration membrane and ro reverse osmosis membrane usage are very high, in the choice of membrane elements, must be for the actual water quality, the comprehensive parameters for comparison. Try to choose more cost-effective membrane elements.

Tips for Using Home Water Purifier Filter Cartridges

Tips for Using Home Water Purifier Filter Cartridges

The Battle of Four Membranes: Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis—Which Reigns Supreme in Water Purification?

The Battle of Four Membranes: Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis—Which Reigns Supreme in Water Purification?

Don't Pay for Stupidity! The Ultimate 2026 Water Purifier Guide: Selection, Pitfalls, and Maintenance All in One Article

Don't Pay for Stupidity! The Ultimate 2026 Water Purifier Guide: Selection, Pitfalls, and Maintenance All in One Article

Working Principle and Core Technology of Water Softening Equipment

Working Principle and Core Technology of Water Softening Equipment