If your home water purifier malfunctions, don't panic—these handy repair tips will help you sort it out with ease.

If your home water purifier malfunctions, don't panic—these handy repair tips will help you sort it out with ease.

Why bother with water purifiers when bottled water is so convenient?

Why bother with water purifiers when bottled water is so convenient?

Essential Guide to Selecting Water Purifiers: 7 Key Questions You Must Understand!

Essential Guide to Selecting Water Purifiers: 7 Key Questions You Must Understand!

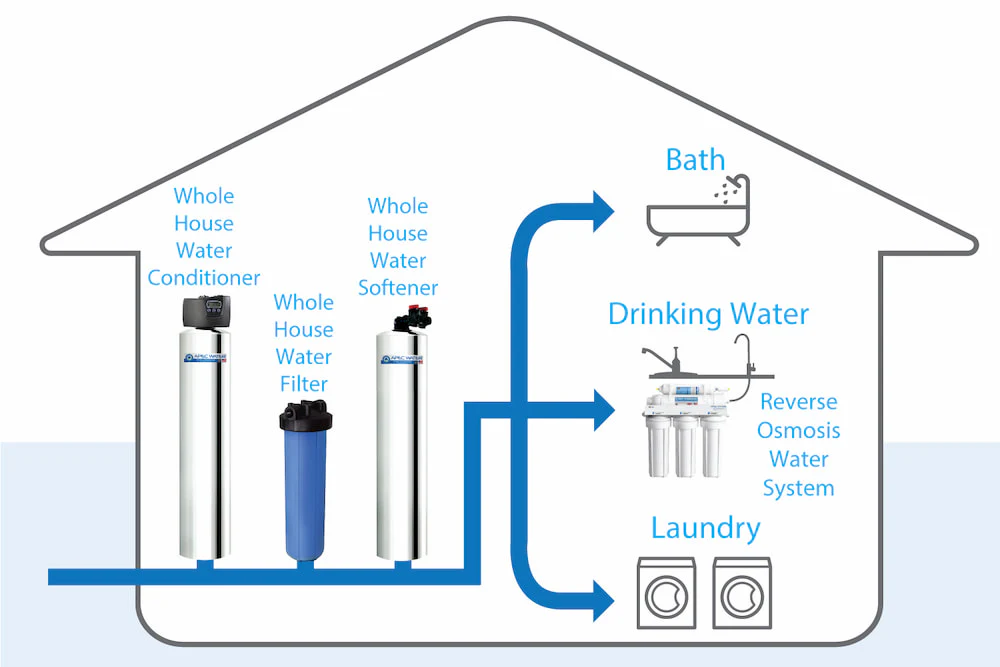

【Avoid Pitfalls Guide】Want to avoid overspending on whole-house water filtration? Here's how to choose wisely!

【Avoid Pitfalls Guide】Want to avoid overspending on whole-house water filtration? Here's how to choose wisely!